Mechanical Ventilation with Heat Recovery Systems

Mechanical Ventilation with Heat Recovery (MVHR) systems have become highly popular in residential new builds. They improve indoor air quality, making for a more comfortable and healthier home environment, and can provide up to 50% savings on energy bills due to the reduced heating demand.

Whilst it was common practice to install MVHR units in lofts, most units are now wall mounted within the heated envelope of the property, usually finding a suitable location in a cupboard. This has made installation far easier and further contributed to their widespread use.

But just how easy is an MVHR system to install?

Clearly, it will depend on the make and model, but most MVHR systems are now very straight-forward to install. Our DMH team will advise on the MHVR systems best suited to your property and work closely with you to formulate an installation plan.

- Identify the location of the MVHR unit

A clear working space is required around the installed unit to allow the cover to be removed and provide sufficient access for maintenance such as filter change.

Allow a minimum of 350mm in front of the unit. The fan must be installed indoors, on a suitable wall away from direct sources of frost, heat and water spray or moisture generation.

- Identify extract / supply areas

The MVHR unit is designed to extract air from all wet rooms e.g. bathroom, kitchen, utility room (with sink). Supply air should be to all habitable rooms e.g. bedrooms and lounge.

Get In Touch

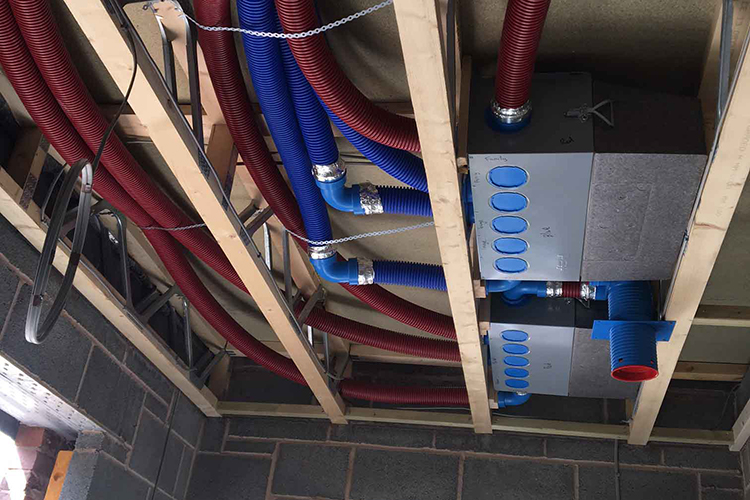

- Install and Seal ducting

Round or flat channel rigid duct should be used and held in place with support straps at regular and precise intervals, making sure that all joints are sealed with silicone. Alternatively, semi-rigid Radial ducting systems are a great way of reducing install time on site. Ducting must be installed in such a way that resistance to airflow is minimised, with bends kept to a minimum. A minimum distance of 300mm between the MVHR appliance and any bends in ductwork is recommended.

- Fit insulation to ducting

Install ducting insulation on the outside of the external air inlet duct and the air outlet duct from the unit, to prevent condensation.

- Install grilles

Extract / input grilles should be valves which are adjustable for commissioning.

- Fix the mounting bracket for MVHR Unit

Fix the mounting bracket to a solid wall, ensuring the interlock side is at the top. If it’s not practical to use a solid wall, the MVHR unit should be fixed to a stud partition.

- Wall mount the MVHR unit and connect to power supply

Install the unit on the wall by ensuring the bracket fixed to the rear of the unit interlocks over the wall mounted bracket.

The cable from the mains power supply should be connected to a fixed wiring installation, via a fused isolator, in accordance with current IEE wiring regulations. For good EMC engineering practice, any sensor cables or switched live cables should not be placed within 50mm of other cables or on the same metal cable tray as other cables. The unit must be earthed.

When you consider we spend around 90% of our time indoors and around 16 hours a day on average at home, the quality of the air we breathe in our home environment matters. An MVHR system dramatically improves that indoor air quality, removing stale damp air and replacing it with fresh, filtered air.

For more information, please get in touch with our professioanl team by calling 01908 803567.